For businesses that need precise parts, custom plastic injection molding is a key process. Sectors like medical, aerospace, automotive, electronics, and industrial equipment need accurate plastic parts to meet strict performance and safety standards. Products need to be accurate because even small changes in size or shape can affect how well they work. Manufacturers use advanced technology and strict quality control to achieve consistent results. From medical devices to automotive safety systems and electronic components, high-precision plastic molding supports product accuracy and compliance with industry regulations. This blog covers its significance and impact across various industries.

Importance of Precision in Specialized Industries

The performance, durability, and safety of products are all directly impacted by precision in custom plastic injection molding. Different industries have specific requirements that depend on accuracy in plastic molding.

Medical Industry

Medical devices require plastic components to meet strict hygiene and safety standards. Parts used in surgical instruments, drug delivery systems and diagnostic equipment must have precise dimensions to function correctly. In healthcare environments, even the smallest defect can cause serious issues. With custom plastic injection molding, companies can make complicated high precise medical parts.

Aerospace Industry

The aerospace sector depends on lightweight plastic components for aircraft and space applications. These parts must be durable enough to handle extreme temperatures, pressure changes, and mechanical stress. Precision is critical because even minor inaccuracies can compromise safety. Manufacturers of injection molding plastic use advanced materials and quality control processes to produce high-tolerance aerospace components.

Automotive Industry

In the automotive sector, precision molding is necessary for making plastic parts that fit and work properly. Engine components, dashboard elements, and safety features require high precision for reliable performance. Plastic parts must also withstand heat, vibration, and exposure to chemicals. Automotive companies can make high-performance parts that meet industry standards with custom plastic injection molding.

Electronics Industry

Electronics manufacturing requires miniature plastic parts to support advanced technologies. Plastic housings, connectors, and circuit board components must have exact dimensions to function properly. Even a small mistake in the molding process can cause problems or connections to fail. Injection molding plastic manufacturers use precision techniques to produce components with tight tolerances for high-tech devices.

Key Factors Affect Precision in Injection Molding

Several factors influence the accuracy of custom plastic injection molding. Achieving high precision requires careful control over mold design, material selection, process monitoring, and quality assurance.

Mold Design and Tooling

The final product’s accuracy depends on the mold’s quality. High-quality molds reduce defects and maintain consistent part dimensions. Factors such as mold cavity alignment, cooling systems, and gate design influence accuracy. Experienced injection molding plastic manufacturers use advanced mold-making techniques to create durable, precise molds.

Material Selection

The final product’s strength, flexibility, and durability depend on the type of plastic that was used in injection molding. Different plastics have unique properties, such as heat resistance, impact strength, and chemical compatibility. Molded parts can meet industry standards if the right material is used. For high-precision uses, engineers choose materials based on factors like shrinkage rates and flow properties.

Process Control and Monitoring

Maintaining precision in injection molding requires strict process control. In real time, factors like temperature, pressure, and injection speed need to be monitor. Automated systems help adjust parameters to minimize variations in production. Injection molding plastic manufacturers use process monitoring technologies to detect and resolve issues before they impact product quality.

Quality Assurance

Quality control is necessary for achieving high precision in molding. Inspection techniques such as coordinate measuring machines (CMM), optical scanning, and X-ray analysis help manufacturers verify part accuracy. Custom plastic injection molding companies follow industry standards to meet regulatory requirements. Strict testing and inspection processes reduce defects and improve consistency.

Advanced Technologies for High-Precision Molding

Modern technology has improved the accuracy, and efficiency of custom plastic injection molding. Injection molding plastic manufacturers keep their tolerances very tight by using high-tech tools and automation.

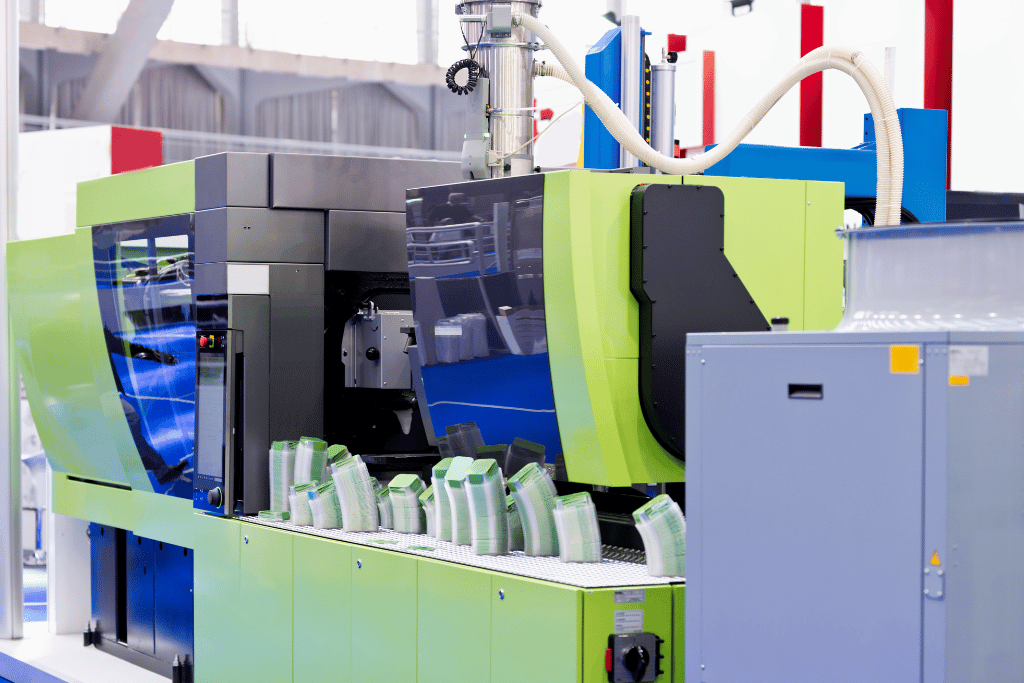

State-of-the-Art Injection Molding Machines

Modern injection molding machines offer high levels of precision and repeatability. The accurate control systems in these machines change the pressure, speed, and temperature so that the products are always the same. High-performance molding machines reduce material waste, and increase production efficiency.

Automation and Robotics

Automated systems are helpful in precision molding. Robotics help with material handling, mold changes and part removal. Automation lowers mistakes made by people and makes production faster. Injection molding plastic manufacturers use robotic systems to improve efficiency, and uphold accuracy in high-volume production.

Precision Measurement Tools

Measuring and inspecting molded parts is essential for quality control. Advanced measurement tools – coordinate measuring machines (CMM) and optical inspection systems, help verify part dimensions. These tools find flaws and changes from the original design, which lets companies fix problems before the products reached the market.

Challenges in Achieving High Precision

Custom plastic injection molding comes with challenges that can affect accuracy. Manufacturers must address issues like material inconsistencies, shrinkage, and warping to maintain high precision.

Shrinkage and Warping

Plastic materials shrink as they cool inside the mold. Uneven cooling can cause warping, which affects part dimensions. Engineers design molds with proper cooling channels to minimize shrinkage and maintain accuracy.

Material Inconsistencies

The properties of different types of plastic may be slightly different, which can affect how precisely the mold is made. Injection molding plastic manufacturers use strict material testing and process adjustments to maintain consistency.

Mold Wear and Maintenance

Over time, molds experience wear, and tear, affecting accuracy. Mold refurbishment and regular maintenance help makers make consistent, high-quality parts.

Business Benefits of Custom High-Precision Injection Molding

Companies that invest in custom plastic injection molding benefit from reliable, high-quality production. Precision molding offers advantages in terms of efficiency, cost savings, and product consistency.

- Consistent Quality: High-precision molding produces uniform parts with minimal defects.

- Reduced Material Waste: Advanced molding techniques optimize material use, lowering production costs.

- Faster Production Cycles: Automation and precise process control reduce cycle times and increase output.

- Industry Compliance: Precision molding meets strict industry regulations for safety and performance.

Choosing the Right Partner for High-Precision Injection Molding

Companies needing precise parts must make sure they choose the right injection molding plastic manufacturers. A reliable manufacturing partner should have experience, advanced technology, and industry certifications.

Key Factors to Consider

When choosing a custom plastic injection molding provider, businesses should look for:

- Expertise in precision molding for specialized industries.

- Advanced equipment and automation for high-quality production.

- Strict quality control measures to meet industry standards.

- Ability to handle complex designs with tight tolerances.

Hansen Plastics: A Trusted Partner

Hansen Plastics provides precision-focused injection molding solutions for industries that require high-performance plastic components. With advanced technology and a commitment to quality, Hansen Plastics delivers reliable, high-precision molding services. Businesses in medical, aerospace, automotive, and electronics sectors can benefit from their expertise and manufacturing capabilities.

Custom plastic injection molding is important for making precise parts for businesses that need them. Businesses can get regular quality, efficiency and compliance with industry standards if they work with the right manufacturing partner.