Decoupled Molding

Revolutionizing Plastic Molding

Precision Meets Versatility in Plastic Molding

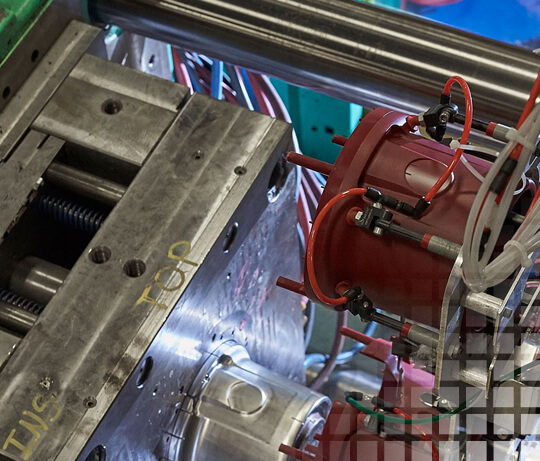

At Hansen Plastics, our Decoupled Molding process transforms traditional plastic molding into an exact science.

By leveraging advanced pressure sensors and RJG software, we achieve unmatched levels of precision, repeatability, and quality in every production run.

How Decoupled Molding Works

Precision in Every Stage

Decoupled Molding is a scientifically driven method designed to provide precision control throughout the molding process. Here’s how it works:

- Pressure Sensors: Strategically embedded within the mold to monitor and adjust pressure in real time.

- Controlled Stages: Divides the process into three distinct phases—fill, pack, and hold—to ensure accuracy and repeatability.

- Enhanced Consistency: Reduces variables like shrinkage and dimensional errors, ensuring each part meets exact specifications.

Advanced Software Integration

The Power of Digital Control

Our innovative approach integrates RJG software with state-of-the-art machinery and Hansen Plastics’ ERP system. This combination enables:

- Real-Time Monitoring: Continuous feedback ensures optimal performance throughout the production cycle.

- Design Optimization: Fine-tuning capabilities allow for intricate designs and complex geometries.

- Streamlined Processes: Seamless integration between design and production minimizes delays and maximizes efficiency.

The Benefits of Decoupled Molding

Precision, Cost Efficiency, and Reliability

Hansen Plastics’ Decoupled Molding process offers several distinct advantages:

- Unparalleled Quality: Advanced technology ensures perfection in every part.

- Cost Reduction: Optimized processes lower production costs and minimize waste.

- Scalability: Efficient workflows support projects of any size, from prototypes to large-scale production.

These benefits make Hansen Plastics a trusted partner for industries demanding high-quality, complex plastic components.

Get Started with Hansen Plastics

Partner with the Experts in Decoupled Molding

With decades of expertise, Hansen Plastics is committed to bringing your designs to life with unparalleled precision and efficiency. Contact us today to learn more about how our Decoupled Molding process can elevate your production and ensure exceptional results.

Why Choose Hansen Plastics for Custom Plastic Injection Molding?

Advanced Technology

Utilizing the latest in injection molding equipment and software

Expert Team

Highly skilled engineers and technicians with decades of experience

Quick Turnaround

Efficient processes to meet your deadlines

Exceptional Quality

Rigorous quality control measures ensure consistent, high-quality parts

Testimonials

“My company is in the water delivery business. My role in the company is a Senior Buyer. I have been doing business with HPC for 4 years, however, the company I represent has been doing business with HPC for over 30 years. During that time I have f... Read More

– Scott Olberding, Senior Buyer, Elkay

“My company is in the Automotive tool business. My role in the company is President. I have been doing business with HPC for 12 years. During that time I have found HPC to be Informative… Once expectations are understood, HPC is an excellent comm... Read More

– Eric Leicher, President, Motive Products

“Because of your support, we will be able to provide our guests with a safe place to sleep, food, clothing, coats, shoes, a hot shower, and laundry facilities.”... Read More

– Sarah J. Ponitz, Executive Director, Pads of Elgin

Industries We Serve with Custom Plastic Injection Molding

Appliances

We provide custom plastic injection molding solutions for the appliance industry.

Fluid Movement

Innovative plastic solutions for fluid movement and water treatment industries.

Transportation

Providing high-quality plastic components for the transportation industry.

Ready to Start Your Custom Plastic Injection Molding Project?

Contact us today to discuss your custom plastic injection molding needs!