Multi-Material Molding: Innovation and Versatility

Advanced Solutions for Complex Molding Needs

At Hansen Plastics, our Multi-Material Molding process delivers innovative solutions for complex product designs. This technique allows for the seamless integration of multiple materials into a single component, improving functionality, aesthetics, and performance across various industries.

How Multi-Material Molding Works

Precision Engineering for Enhanced Performance

Multi-material injection molding enables the combination of two or more materials in a single process. This advanced method is ideal for producing parts that require multiple textures, colors, or mechanical properties. Key advantages of multi-material molding include:

- Enhanced Product Design: Allows for aesthetic and functional material combinations.

- Improved Durability: Combines rigid and flexible materials for added strength and usability.

- Cost and Assembly Efficiency: Reduces the need for secondary manufacturing and assembly steps.

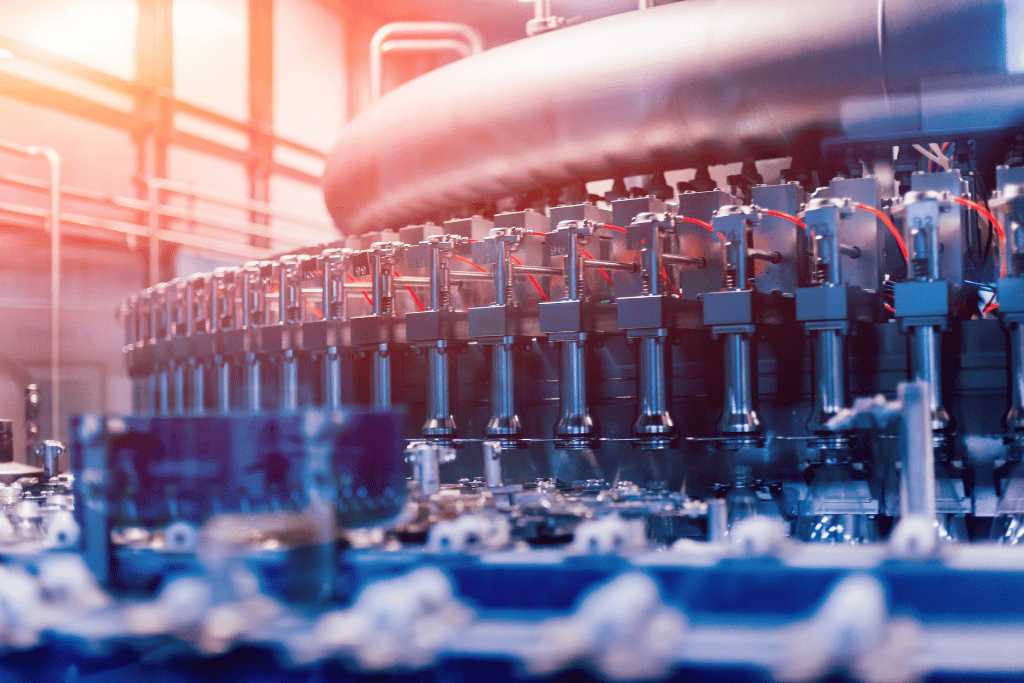

Advanced Machinery and Expertise

Optimized for High-Performance Results

Hansen Plastics utilizes cutting-edge multi-material injection molding machines to ensure superior results.

Our experienced team carefully oversees each stage, from material selection to final production, ensuring that each component meets strict quality standards.

By leveraging state-of-the-art technology and decades of expertise, we provide high-precision solutions that enhance durability and reduce production costs.

The Benefits of Multi-Material Molding

Efficiency, Strength, and Design Flexibility

Our multi-material molding process offers key advantages for industries requiring advanced, high-performance components:

- Greater Design Possibilities: Enables seamless integration of different textures, colors, and mechanical properties.

- Stronger, More Functional Parts: Ideal for products requiring soft-touch grips, seals, or ergonomic enhancements.

- Reduced Production Costs: Eliminates the need for separate assembly, reducing time and material waste.

These benefits make multi-material molding a valuable solution for industries such as automotive, medical, and consumer goods.

The Molding Process

A Step-by-Step Approach to Quality

Our multi-material molding process is carefully managed to ensure precision, strength, and efficiency in every product. The steps include:

- Material Selection: Choosing the right combination of rigid and flexible plastics for optimal performance.

- Mold Preparation: Setting up the multi-shot or overmolding system for precise material placement.

- Injection Process: Injecting the first material followed by the second, ensuring a seamless bond.

- Cooling and Solidification: The part cools and solidifies, maintaining exact dimensions and material integration.

- Part Ejection: The final component is carefully removed, ensuring flawless quality and performance.

By combining expert craftsmanship with leading-edge technology, Hansen Plastics delivers multi-material molding solutions that meet the highest industry standards.

Get Started with Hansen Plastics

Partner with Hansen Plastics for Multi-Material Molding Excellence

Multi-Material Molding at Hansen Plastics provides cutting-edge solutions for complex, high-performance plastic components. Contact us today to learn how our expertise can enhance your product design and manufacturing process.

Why Choose Hansen Plastics for Custom Plastic Injection Molding?

Advanced Technology

Utilizing the latest in injection molding equipment and software

Expert Team

Highly skilled engineers and technicians with decades of experience

Quick Turnaround

Efficient processes to meet your deadlines

Exceptional Quality

Rigorous quality control measures ensure consistent, high-quality parts

Testimonials

“My company is in the water delivery business. My role in the company is a Senior Buyer. I have been doing business with HPC for 4 years, however, the company I represent has been doing business with HPC for over 30 years. During that time I have f... Read More

– Scott Olberding, Senior Buyer, Elkay

“My company is in the Automotive tool business. My role in the company is President. I have been doing business with HPC for 12 years. During that time I have found HPC to be Informative… Once expectations are understood, HPC is an excellent comm... Read More

– Eric Leicher, President, Motive Products

“Because of your support, we will be able to provide our guests with a safe place to sleep, food, clothing, coats, shoes, a hot shower, and laundry facilities.”... Read More

– Sarah J. Ponitz, Executive Director, Pads of Elgin

Industries We Serve with Custom Plastic Injection Molding

Appliances

We provide custom plastic injection molding solutions for the appliance industry.

Fluid Movement

Innovative plastic solutions for fluid movement and water treatment industries.

Transportation

Providing high-quality plastic components for the transportation industry.