Injection-molding automation is transforming the plastics industry, allowing plastic companies to achieve unprecedented levels of efficiency, quality, and consistency. By integrating robotics, vision systems, and advanced manufacturing-execution software, molders reduce cycle times, minimize defects, and provide detailed traceability, enabling a new era of “lights-out” production.

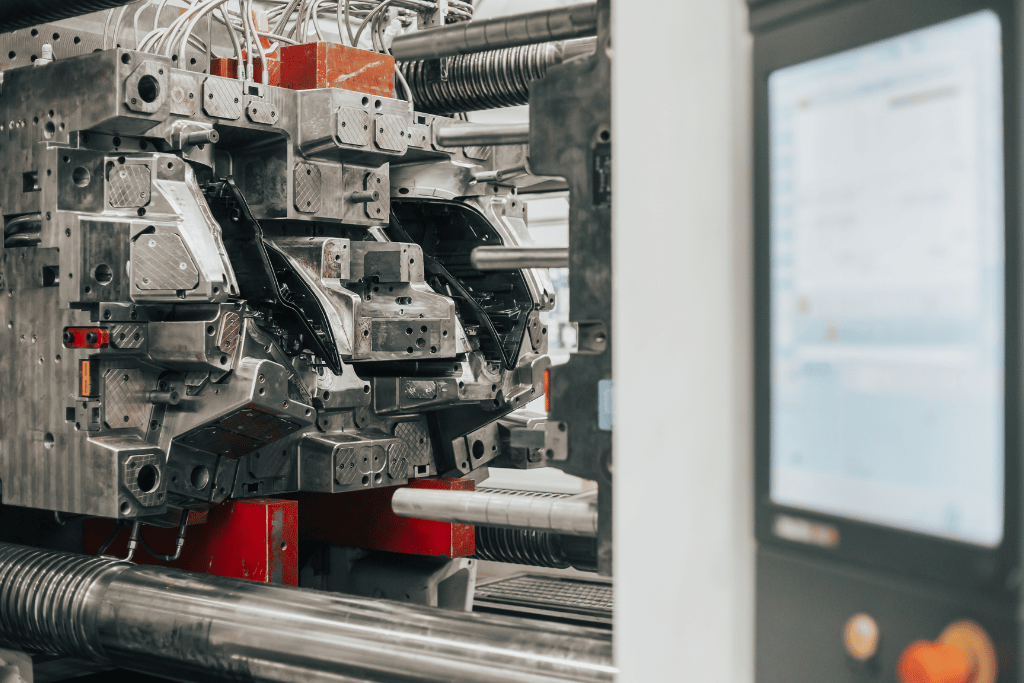

Robotics and Part Handling

Robotic arms have become a staple on modern molding cells, handling parts with speed and precision that outpace human operators. As soon as a molded component ejects, a six-axis robot positions itself to remove the part, deposit it onto a conveyor, or load it into a secondary inspection station. The robot’s ability to repeat the same movements within fractions of a millimeter prevents part damage, especially on delicate or geometrically complex components. End-of-arm tooling can be custom-designed to pick up multiple parts at once or accommodate inserts, further reducing cycle time by blending removal and staging steps. These automated cells often run for extended shifts without interruption, minimizing downtime and preserving consistent part quality.

Vision Systems for Real-Time Inspection

In-machine vision cameras are now integrated directly into molding cells to inspect parts immediately upon ejection. High-resolution cameras capture the molded geometry, surface finish, and color uniformity, comparing each shot against stored “golden” images. When a deviation appears, whether a flash at a gate, a missing feature, or a color mismatch, the system rejects the part before it enters downstream processes. This on-the-fly inspection eliminates manual gauging stations and drastically cuts scrap rates. Vision systems also read datamatrix codes or engraved serial numbers on every part, tying each molded batch back to specific tool cavities and shift times. As a result, quality engineers can trace any defect to its precise cause, whether it was a mold-temperature fluctuation or a resin-lot change.

Closed-Loop Process Control with MES Integration

Manufacturing-execution systems (MES) now directly connect to injection presses, capturing sensor data, such as cavity pressure, barrel temperature, and screw position, at intervals measured in milliseconds. This real-time data logging allows engineers to set upper and lower limits on key process parameters; if a measure drifts beyond those bounds, the MES triggers an alarm or automatically pauses production. Historical data from each shot feeds into statistical process-control charts, revealing subtle trends before they turn into nonconforming parts. Integration with enterprise resource planning (ERP) systems ensures that upstream demands and downstream shipping schedules adjust dynamically as production rates change. Plastic companies can therefore allocate resources more precisely, reduce inventory, and respond swiftly to new orders.

Automated Tool Calibration and Maintenance

Newer molds come equipped with embedded thermocouples, pressure transducers, and RFID-based identification tags. At the start of each run, a calibration routine verifies that sensor readings match expected reference values. Should a sensor signal fall outside its calibration window, the system notifies maintenance technicians to replace or recalibrate before any parts are produced. Predictive-maintenance algorithms analyze vibration or temperature data from hydraulic units and mold platens to forecast when bearings or seals will require service. The result is fewer unplanned shutdowns and extended tool life, both of which directly reduce cost and improve uptime.

Data-Driven Optimization and Digital Twins

As plastic companies adopt Industry 4.0 practices, digital twins of molds and presses guide molding-parameter refinement. By simulating fill patterns, cooling profiles, and tool deformation under pressure, engineers predict issues, such as warpage or sink marks, before the mold arrives on the shop floor. During production, real-time feedback further refines these models, creating a closed loop that continuously improves performance. For example, if a digital twin predicts that increasing pack time by a fractional second would reduce residual stress in a critical zone, the MES can adjust that parameter automatically on subsequent shots. This approach accelerates cycle development, shortening the ramp-up phase by 30 to 50 percent.

Collaborative Robots and Flexible Cells

Cobots, or collaborative robots, work side by side with human operators to perform tasks that require both dexterity and strength. In many molding cells, a cobot assists an operator by placing inserts into the mold or handling small, intricate parts that are difficult for larger automation. Once the robot is programmed, it can replicate these tasks without fatigue or error. Flexible automation cells can switch between different mold families in under an hour by using quick-change platens and standardized robot programming. This flexibility is crucial for plastic companies serving multiple markets, such as automotive, medical, and consumer electronics, where production runs may vary from thousands to millions of parts.

Future Trends in Molding Automation

Looking ahead, artificial intelligence (AI) will play a greater role in predictive analytics applications. Machine-learning algorithms will analyze years of molding data to suggest when a mold cavity will require maintenance or when a new resin lot might shift fill behavior. Augmented-reality (AR) tools will overlay maintenance instructions onto a technician’s field of view, reducing intervention times and preventing costly errors. Additive-manufactured conformal cooling inserts will become more common, further reducing cycle times by 20 to 30 percent while improving part uniformity. Finally, edge-computing devices that process sensor data locally will decrease network latency, allowing critical control decisions, like pack-pressure adjustments, to occur within microseconds rather than milliseconds.

Injection-molding automation has evolved from simple robots and vision checks to fully integrated, data-driven production ecosystems. By embracing robotics, vision systems, MES integration, and digital twins, plastic companies achieve higher throughput, fewer defects, and rapid response to market demands. As AI and AR mature, molding cells will become even more intelligent and self-optimizing. To explore automated solutions for your next project, contact Hansen Plastics Corporation for expert guidance on robotic integration, process control, and turnkey automation planning.