If you have ever asked for an injection molding quote and thought, “Why is this higher than I expected?”, you are not alone. Injection molding cost is not one simple number. It is the sum of tooling decisions, resin selection, cycle time, press requirements, labor, quality expectations, secondary operations, packaging, and logistics.

This guide breaks down the most common injection molding cost drivers and shows how to estimate a realistic budget for your part or program. The goal is budget clarity so procurement and engineering can align early and avoid expensive changes later.

The big picture: one-time costs vs recurring costs

Before you estimate anything, separate your costs into two categories:

One-time (typically upfront)

-

Injection mold tooling (and any fixtures or gauges)

-

Tool design and engineering time

-

Sampling and validation activities (as required)

-

First article documentation, if requested

Recurring (per part or per order)

-

Resin and additives

-

Machine time and cycle time

-

Labor and handling

-

Scrap and regrind policy

-

Quality inspection (in-process and final)

-

Secondary operations

-

Packaging and labeling

-

Freight and logistics

Most budget surprises happen when teams assume recurring costs are “just resin,” or assume tooling is a fixed number without understanding what is included.

Tooling cost: what actually changes the price of the mold

Tooling is often the largest line item, and it varies widely. The reason is simple: the tool is an engineered machine built around your part requirements.

Key drivers of injection mold tooling cost include:

Part geometry and complexity

-

Deep ribs, thin walls, or complex shutoffs can increase machining time and risk

-

Tight tolerances can require more precise tool build and more tuning

-

Challenging ejection can force more complex mechanisms

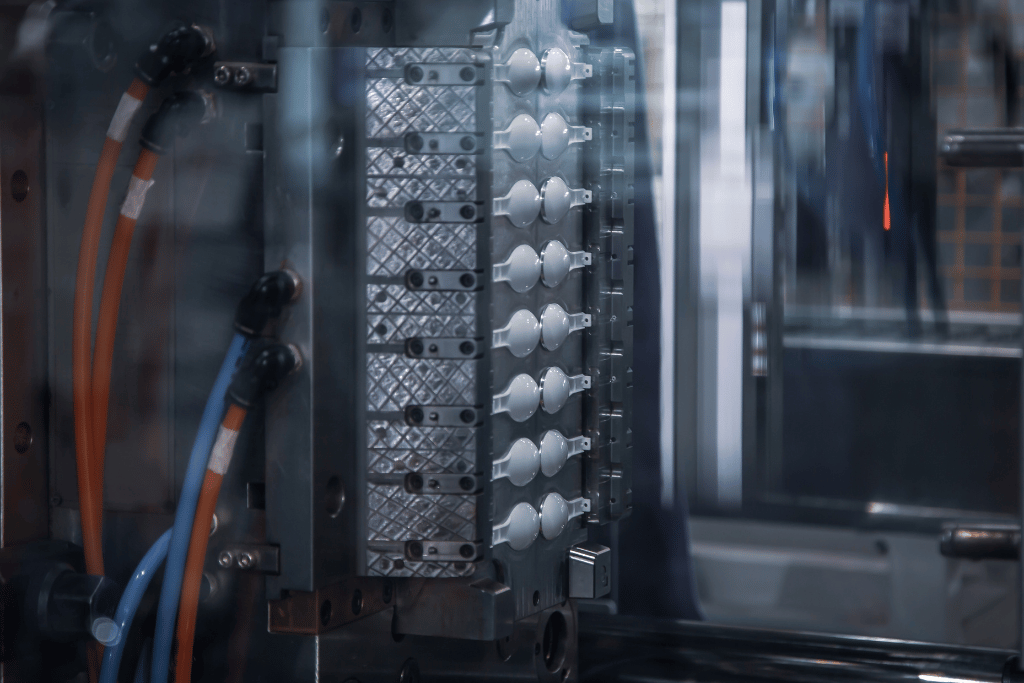

Cavity count

More cavities can lower piece price, but they increase tool cost. The tradeoff depends on:

-

Annual volume

-

Required takt time

-

Press availability and part yield expectations

Tool class and expected life

A tool designed for low volume production is not built the same as a tool expected to run millions of cycles. Steel selection, wear components, and build approach all change cost.

Tooling type and features

-

Hot runner vs cold runner

-

Unscrewing mechanisms, slides, lifters

-

Textures and cosmetic requirements

-

Conformal or advanced cooling strategies (where applicable)

Budget tip: When requesting a quote, ask for tooling options (for example, a lower cavity count option and a higher cavity count option) so you can understand the cost vs piece price tradeoff.

Resin cost: the most visible driver, but not the only one

Material often gets the most attention because it is easy to price. But resin impacts cost in multiple ways beyond the price per pound.

What changes resin cost

-

Commodity vs engineered resin

-

Fillers (glass, mineral) and specialty additives

-

UV stabilization, flame retardants, or impact modifiers

-

Color requirements and color matching controls

How resin affects processing cost

Some materials require:

-

Drying systems and moisture control

-

Higher melt temperatures and longer cycles

-

Increased wear on screws and tooling (especially filled resins)

-

Tighter process windows to maintain part performance

So even if the resin price difference looks small, it can still change your overall injection molding cost through cycle time and scrap risk.

Cycle time and press time: where budgets win or lose

In many quotes, cycle time is the biggest controllable driver of piece price. A few seconds can matter a lot at scale.

Cycle time is influenced by:

-

Wall thickness and cooling time

-

Material type and melt temperature

-

Part ejection difficulty

-

Mold cooling design and water flow

-

Cosmetic requirements that limit allowable process changes

Press time cost is not only “seconds per part.” It also depends on:

-

Press tonnage required to run the tool safely

-

Machine hourly rate and shop utilization

-

Setup time, changeovers, and run size

Budget tip: Ask the molder to state the assumed cycle time, press tonnage, and cavity count in the quote. Without those assumptions, two quotes are rarely comparable.

Labor, handling, and quality expectations

Not every part can be dropped into a bin and shipped. Labor costs rise when a program requires:

-

Manual part handling to protect cosmetics

-

Trimming, de-gating, or deflashing

-

Bagging, counting, or kitting

-

Labeling, barcode requirements, or special packaging

-

Additional inspection steps or documentation

Quality expectations also affect cost. Examples:

-

100% inspection vs sampling plans

-

Measuring tight tolerances vs basic go/no-go checks

-

Traceability requirements tied to lots or production runs

None of these are “bad.” They just need to be visible in the budget early.

Secondary operations: common add-ons that change quotes fast

Secondary operations can rival molding cost depending on the part. Common examples:

-

Insert installation or insert molding

-

Ultrasonic welding or assembly

-

Pad printing, heat staking, labeling, laser marking

-

Drilling, tapping, or post-machining

-

Surface finishing or coating

Budget tip: If you think you might need a secondary operation, mention it in the RFQ even if it is “optional.” Suppliers can include a line-item add-on so you can make decisions with real numbers.

Packaging and logistics: easy to overlook, painful later

Packaging is usually treated as a detail until it becomes a problem. Packaging affects:

-

Labor time

-

Cosmetic protection and scrap rates

-

Freight efficiency and damage claims

Clarify:

-

Bulk pack vs bagged vs individual compartments

-

Carton labeling requirements

-

Pallet configuration

-

Shipping cadence (weekly, monthly, Kanban-style replenishment)

Freight and logistics can also change total landed cost depending on:

-

Distance and shipping method

-

Rush shipments due to missed schedules

-

Storage and inventory handling expectations

How to estimate a realistic injection molding budget

Here is a simple way to build a budget that holds up in internal planning.

Step 1: Confirm program basics

-

Annual volume and ramp plan

-

Resin family and any additives

-

Cosmetic and tolerance requirements

-

Expected packaging style

Step 2: Get tooling range, not a single number

Request at least two tooling approaches:

-

Low volume or bridge tooling option (if applicable)

-

Production tooling option aligned to your program life

If you have uncertain volumes, this is the fastest way to protect cash flow.

Step 3: Ask for the quote assumptions

For piece price, confirm:

-

Cavity count

-

Cycle time

-

Press tonnage

-

Scrap assumption

-

Inspection plan

-

Packaging style

Step 4: Separate recurring costs into line items

Build a budget like:

-

Resin

-

Molding

-

Secondary ops

-

Inspection/documentation

-

Packaging

-

Freight

This makes it much easier to explain cost changes internally when engineering revisions happen.

Step 5: Add a change buffer

Early budgets should include a buffer for:

-

Engineering changes during DFM

-

Tool tuning iterations

-

Validation requirements you may not know yet

-

Early scrap during ramp

Even a small buffer can prevent a program from being labeled “over budget” when it is actually just maturing.

RFQ questions that improve cost accuracy

If you want better quotes, ask better questions. Include these in your next RFQ:

-

What cycle time are you assuming and what drives it?

-

What cavity count are you quoting and why?

-

What press tonnage do you expect to run on?

-

What resin grade and color approach are assumed?

-

What scrap percentage is included in the quote?

-

What inspection plan is included, and what is extra?

-

What packaging method is included, and what alternatives exist?

-

What secondary operations are included or excluded?

-

What tooling scope is included (hot runner, spares, sampling quantity)?

-

What items would cause a change order after award?

These questions force clarity and reduce the “quote gap” between early budget numbers and real production cost.

Cost clarity is a sourcing advantage

When procurement and engineering understand what drives injection molding cost, you can make smarter decisions early: adjust a feature to reduce cycle time, choose the right tool strategy, or right-size inspection instead of paying for unnecessary overhead.

If you want a fast, practical cost review, a qualified molder should be able to look at your part requirements and explain where the biggest cost levers are and what tradeoffs are worth considering before you commit to tooling.