For those already operating under the Lean methodology for production, it can be easy for teams to become complacent and fall out of sync with the underlying philosophy of Lean, instead falling into a pattern of going through the same motions without applying critical examination in how to promote and execute improvements to the value stream. But to reinvigorate the Lean philosophy and get back on track, it may not be enough to re-tread the same teachings—instead, it may be necessary to present a concurrent methodology with similar results to steer the ship back on course.

While not a direct piece of Lean production, the ideas of the 4 Disciplines of Execution, or 4DX, embody many of the same virtues, and by understanding them, 4DX can provide an additional framework to reinforce the core Lean practices of a workplace. Much like Lean, 4DX focuses on simplification of information and achieving direct goals by specialized teams. More specifically, as the name implies, 4DX relies on four pillars:

- Discipline 1: Focus — Extraordinary results can only be achieved when you are clear about what matters most. This means fixating on a singular goal until that goal is achieved. To make this possible, it must be real, and actionable. This is the Wildly Important Goal (WIG). To get the most out of a WIG, frame it as “from (X) to (Y) by (when)”.

- Discipline 2: Leverage — Achieve more with less. Identify the items and actions that have the greatest potential for achieving the WIG. These are the lead measures.

- Discipline 3: Engagement — Play to win. Framing the WIG as actionable means it can determined as “winnable”. As such, create a scoreboard that is visible, updated, and simple to understand, to keep team members informed and involved.

- Discipline 4: Accountability — The only way to make something happen is to do it. Create milestones, share learnings, and review the scoreboard regularly during once-a-week stand-up meetings of no longer than 20 minutes. Once milestones have been achieved, update the scoreboard, and create new milestones until the WIG is achieved.

The terminology may be new, but the ideas should be clicking for those versed in Lean. Namely, because these four pillars of 4DX almost perfectly align with the PDCA method of Lean — Plan, Do, Check, Act.

Also similar to the Lean idea of focusing employees through Kaizen events of specialized, cross-disciplinary teams, the first pillar of 4DX — establishing the Wildly Important Goal — requires creating a specialized team to focus on just that goal. Multiple teams can be created, but each team should have no more than one goal to focus on, to keep the disciplines flowing from one step to the next, and to emphasis the achievability of each WIG.

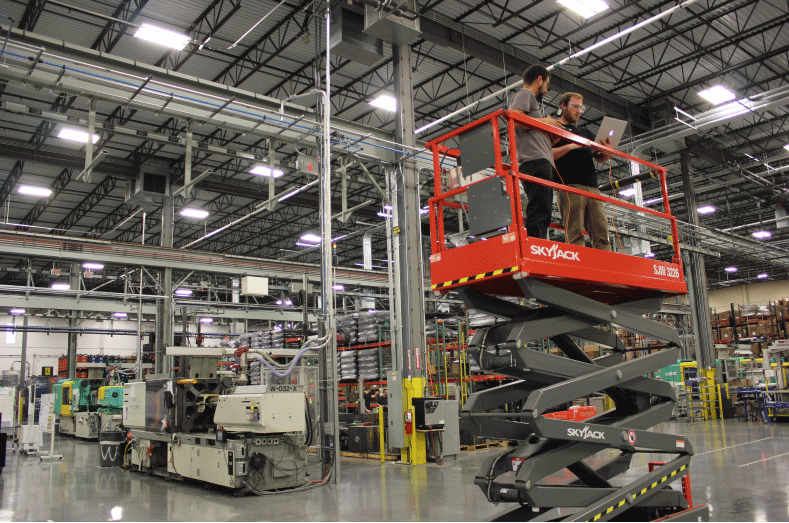

All in all, the 4DX framework sets out to achieve the same fundamental purpose of Lean — continuous improvement by maximizing finite resources to identify and eliminate waste. Much like how hearing the right answer from someone else makes it more obvious than trying to get there by oneself, sometimes an old idea becomes easier to handle when said in new way. Committed to both Lean and 4DX methodologies, Hansen Plastics Corporation employs both to fulfill a commitment to their mission of providing the highest quality injection molded products and services to a diverse client base, ensuring customer satisfaction, trusting relationships, and sustainable, profitable growth. Undertaking a philosophy of continuous improvement to continue improving, expanding, and adaption over 40 years, Hansen Plastics has continuously maintained goals for their customers and still seeks new technologies and applications to expand their services and business offerings.

To learn more about Hansen Plastics Corporation, their techniques, and their business philosophy, visit Hansenplastics.com and click to learn more about our markets served, like the injection molding for appliances and automotive industries.