Prototyping is an essential step in the manufacturing process. It’s a cheap, easy way to make effective plastic parts. Prototypes help ensure successful production with fewer mistakes. Using prototypes helps you get it right the first time when you’re making a part for large-scale production. Hansen Plastics has the tools and skills necessary to create the prototypes you need for your next injection molding project.

Manufacturers use prototypes for lots of reasons. When you need a plastic part that is a specific size and needs precision, quick prototyping is a quick way of adjusting things until you get them just right. You can create test parts to be sure they’re perfect before you start manufacturing them. It prevents major mistakes and waste throughout the production process, saving time and money in the long run.

Your idea has to live up to its purpose in your industry. You may have a design, but having a prototype of the final product is important. Even if it’s not required, a working prototype can be very helpful. This investment has many advantages that are well worth the cost to the manufacturer. You want your idea to be impressive and stand out among the rest. A working prototype helps you create your product design in full detail.

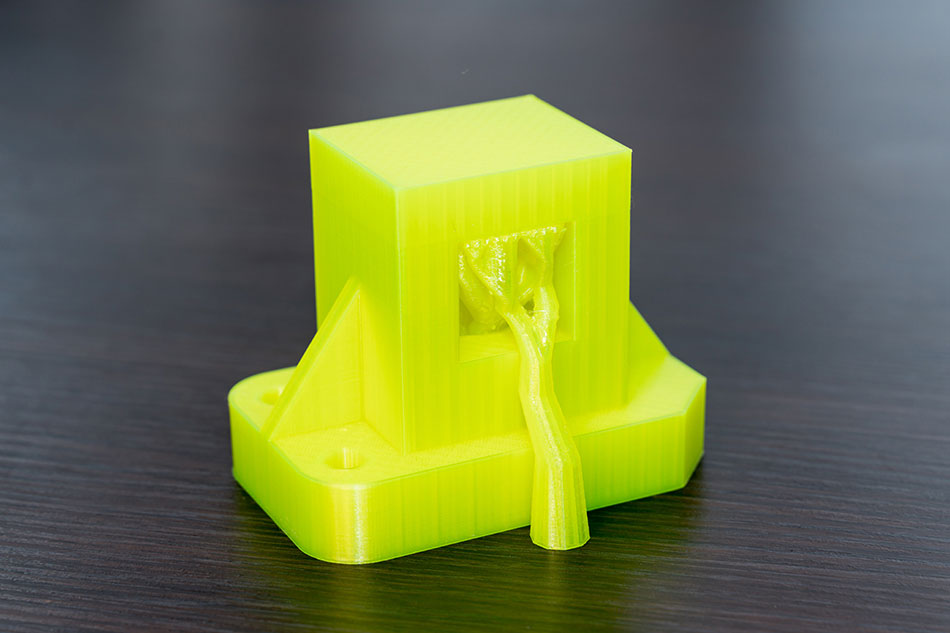

If something needs to be redesigned, prototypes can show you areas that might need improvement better than software sometimes can. You can start developing pictures and written instructions for your product from the prototype. It can reduce development time in getting your final product on the market. Getting your parts completed before your competitors is always great for business.

If something needs to be changed to make a part more functional or precise, when you’re using prototypes at least you won’t have hundreds or thousands of the final part made incorrectly. Prototypes reduce product development time drastically. They offer a way to verify the accuracy of each step throughout the manufacturing process until your product is ready to market. Prototypes help keep production on track and costs lower.

Samples and test products are important to have on hand to show employees, clients, potential customers, and investors. They are great for displays and trade shows as well. When you want to be able to show your associates what you’re talking about instead of just trying to explain it, a prototype can be a good example to show them. They will be able to see your progress firsthand.

Having prototype samples is a huge advantage for production and marketing purposes. The final product has to have accurate dimensions, functionality, and the desired finish. You can save time and money on your project overall with prototypes. This specialized capability ensures that your product design is accurate before starting the tooling process and mass production. The final tools and molds are expensive and take time to make. Mistakes can be costly and time-consuming at this stage in the game.

Having a prototype for your injection molding project is important. You want to make sure the product functions as intended and that its dimensions and specifications are precise before moving forward to the next steps in the process. Prototypes give you working examples of your product to show your team, clients, and potential buyers. Having a prototype will save time and cut costs on the project and give you a marketing tool to display. Hansen Plastics can help, call today.