Complex parts requiring tight tolerances and precise insert placement often challenge horizontal presses, where gravity can work against designers. In precision manufacturing, vertical molding turns gravity into an asset by clamping the tool upright and ensuring consistent insert seating, exact wall thickness, and minimal flash. For Illinois plastic injection molding partners, this approach delivers unmatched accuracy and repeatability for high-value applications.

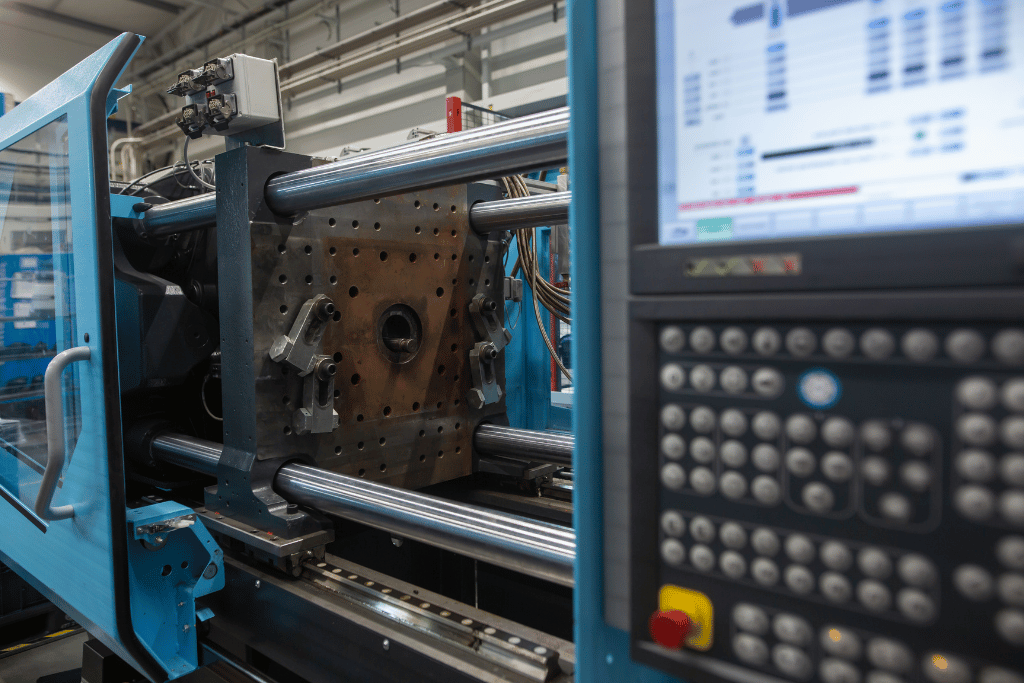

Why Vertical Molding Delivers Superior Precision

When the mold closes vertically, inserts drop directly into the cavity and stay aligned while the tool closes. That alignment prevents the slight shifts that can cause misaligned holes or uneven wall thickness in a horizontal press. Gravity holds delicate components such as metal bushings, electronic sensors, or threaded brass inserts firmly in place, so every shot matches the validated design without secondary rework.

Key Features That Enable Exacting Results

Platen configurations with fully articulated rotary tables permit one station to accept inserts, a second to perform injection, and a third to eject and inspect parts without interrupting the cycle. Tie-bar-less clamps provide unobstructed access, letting six-axis robots handle intricate insert geometries without collision. Integrated hot-sprue tooling reduces thermal variation, ensuring that polymer flow remains stable even around small cores or tight rib sections.

Design Considerations for Illinois Plastic Injection Molding

Gate location becomes critical when molding vertically. Placing the gate directly opposite an insert ensures uniform packing around the feature, eliminating sink marks and voids. Vent design must evacuate air in deep cavities before the melt front advances, preventing short shots and knit lines. When over-molding multiple materials, engineers sequence the injection steps so each layer bonds without thermal damage to the previously molded sections.

Practical Industry Applications

A medical valve housing requiring a stainless-steel plunger insert and TPE seal performed flawlessly after moving from a horizontal to a vertical two-station rotary cell. The insert remained perfectly centered, so the sealing lip met tolerances within ten microns. An aerospace connector over-molded with polyphenylene sulfide upheld strict dielectric and dimensional requirements because the tool’s vertical orientation eliminated insert tilt during fill.

Advanced Capabilities in Illinois

Partnering with Illinois plastic injection molding specialists brings proximity to rapid-turn tool services and in-house validation labs. Engineers can iterate mold designs using digital twins of the vertical cell, simulating flow and cooling long before steel is cut. When a tool arrives, cavity sensors record real-time pressure curves that match the simulation within five percent, ensuring first-shot success. Clean-room vertical cells then produce precision parts for medical, automotive, and aerospace customers with consistent quality.

Future Trends in Precision Vertical Molding

Vision-guided robots will soon confirm insert orientation and spring placement before each cycle, preventing human error. Servo-electric rotary tables will index to within one thousandth of a degree, essential for multi-shot over-molding where each layer must align perfectly. Conformal cooling designed by metal-additive processes will reduce cycle times by thirty percent, maintaining uniform wall thickness on intricate geometries without warpage.

When part geometry demands exact tolerances and precise insert integration, vertical molding offers a clear advantage over horizontal presses. By collaborating with Illinois plastic injection molding experts, manufacturers accelerate development, minimize scrap, and achieve consistent part quality at scale. To explore vertical molding solutions for your next precision program, contact Hansen Plastics Corporation for tooling reviews, material recommendations, and pilot-cell planning.