Decoupled molding separates the fill, pack, and hold phases into independently controlled steps. By monitoring cavity pressure and adjusting parameters for each stage, plastic decoupled molding delivers repeatable part dimensions, reduces defects, and accelerates cycle development, especially important for injection molding plastic manufacturers aiming for zero-defect production.

Why Traditional Molding Faces Limits

In conventional molding the fill and pack phases overlap. Once the screw switches from velocity to pressure control any variation in material viscosity or mold temperature can cause inconsistencies in part weight, dimensions, or mechanical properties. Those variations lead to warpage, sink marks, flash, or short shots. Engineers may chase process drifts with incremental adjustments but without direct feedback from the cavity the root cause often remains hidden until parts fail inspection.

How Decoupled Molding Fixes Common Defects

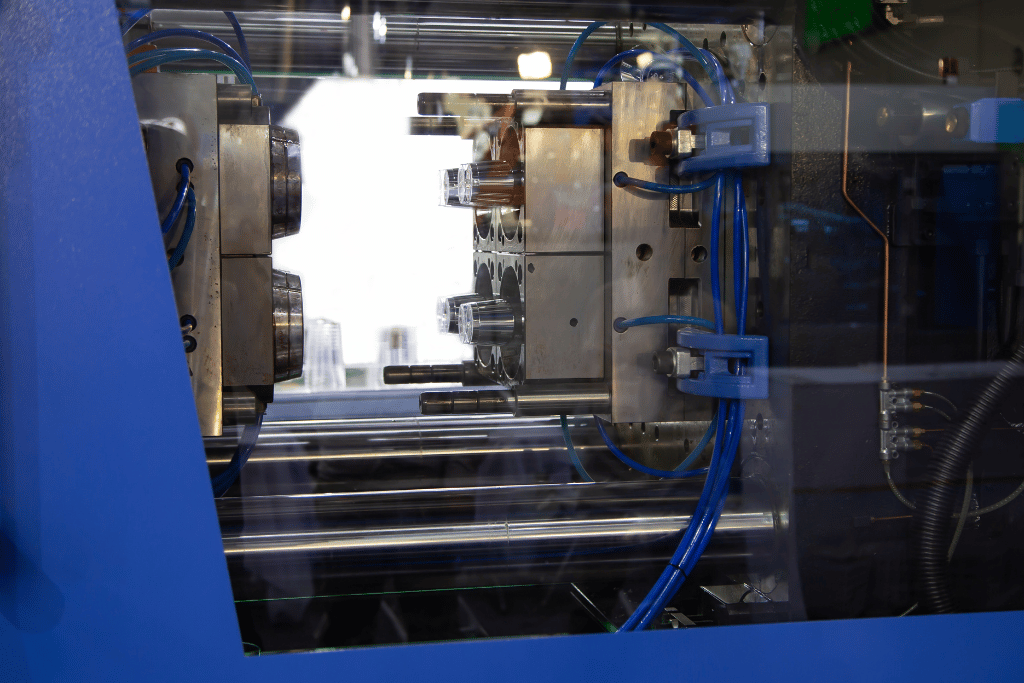

- Controlled Fill: The resin fills the cavity at a set velocity until a defined pressure threshold indicates the cavity is full. Sensors in the mold track the pressure rise and signal when to stop the fill phase.

- Isothermal Pack: After fill completion the system holds melt temperature constant and allows pressure to equalize before applying pack pressure. Gate-seal sensors confirm that the gate has solidified, preventing backflow during packing.

- Precision Hold: A timed hold applies enough force to compensate for shrinkage without overpacking. Cavity sensors maintain exact pressure at critical locations until the part reaches sufficient rigidity.

By decoupling these stages engineers eliminate overlap between velocity and pressure modes. That prevents sudden pressure spikes causing flash around sharp corners or runners. Dimensional consistency improves because every cycle matches the validated cavity-pressure profile regardless of ambient or material-lot changes.

Key Benefits for Injection Molding Plastic Manufacturers

- Defect reduction results from sensor-driven transitions that eliminate warpage and sink marks, cutting scrap rates

- Faster process development replaces trial-and-error runs with real-time pressure data, trimming validation time by up to fifty percent

- Improved material utilization prevents overpacking and flash, keeping shot weights within tight tolerances and lowering resin cost per part

- Enhanced process capability (Cpk) raises statistical control on critical dimensions, often exceeding 1.67 after decoupling

- Robust production under changing conditions adapts pack-and-hold times automatically to humidity or viscosity shifts

Implementing Decoupled Molding on the Shop Floor

- Install cavity-embedded sensors at flow fronts, thick bosses, and thin walls to capture real-time pressure and temperature data

- Upgrade press controllers with decoupled-III or equivalent logic to interpret sensor inputs and sequence fill, pack, and hold automatically

- Design molds with vents and balanced runner layouts that allow uniform pressure development and precise detection of fill completion

- Qualify each resin lot by running fill-to-pack curves under varied conditions and storing optimal profiles for automatic adjustment

- Train technicians to read pressure curves and rely on data-driven decisions instead of manual tuning

Real-World Example: Eliminating Knit-Line Defects

A thin-wall component with a ribbed boss often developed visible knit lines when filled at high speed. By switching to plastic decoupled molding engineers:

- Placed a cavity sensor near the knit region to detect flow-front arrival

- Programmed the press to switch to pack before the two melt fronts met, ensuring uniform pressure before fusion

- Maintained hold pressure until both fronts fully fused, preventing any knit-line weakness

The result was a 95 percent reduction in knit-line visibility, a significant gain in tensile strength at that location, and zero scrap due to cosmetic defects.

Advanced Diagnostics and Continuous Improvement

Sensor data from decoupled molding feeds into the manufacturing-execution system. Over time the MES accumulates thousands of shot signatures so analysts can identify trends, such as gradual tool wear or resin-lot shifts, and flag them before they cause quality issues. This proactive approach moves manufacturers from reactive fire-fighting to preventive maintenance and continuous process improvement.

Achieving Zero-Defect Production

By separating fill, pack, and hold under precise sensor control plastic decoupled molding solves common defects, accelerates validation, and elevates capability. Injection molding plastic manufacturers that adopt decoupled techniques gain consistent part quality, reduced waste, and a clear path to zero-defect production. To explore retrofitting existing presses or building new decoupled cells, contact Hansen Plastics Corporation for consulting, tooling design, and turnkey implementation.