Many industries today require small, detailed plastic parts that may include metal pieces. Making these intricate parts is not easy. Vertical molding is particularly useful in this situation. This unique molding method allows for the creation of parts with complex shapes and small dimensions while saving time and space.

This article talks about how vertical molding works, why it’s great for complicated shapes, and how plastic manufacturers use it to make strong, high-quality parts.

What is Vertical Molding?

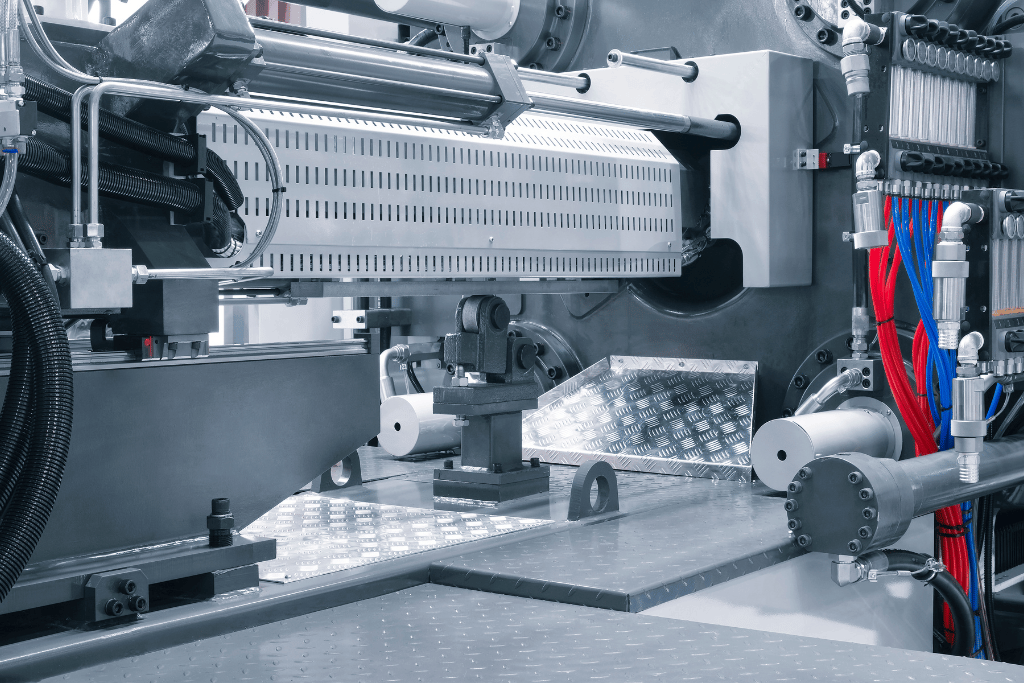

It is a type of injection molding where the mold opens and closes in a vertical direction, rather than horizontal. The final shape is made by cooling the plastic after it has been melted and poured into a mold. The mold’s vertical position makes it easier to add metal or other parts (called inserts) before the plastic is added.

This method is widely used for making plastic parts that need something placed inside them — like wires, metal pins, or screws. They are often built into vertical molding machines so that it’s easy for a person or a robot to put these in before the plastic is injected.

Compared to the more common horizontal molding machines, it offers better control and flexibility, especially when working with small or detailed parts.

Why is Vertical Molding Good for Complex Shapes?

Some plastic parts are made in very complicated ways. Sometimes these parts need to fit very well with other parts because they have small details, thin walls, or unique features. Molding machines don’t always make it easy to make these kinds of shapes.

Here’s Why Vertical Molding is Great For Making These Complex Parts:

1. Better Insert Placement

This type of molding works best when metal or other materials are put into the mold before the plastic is added. That’s what they’re called. It’s great for parts that need to be strong or have different kinds of materials. The vertical setup holds the insert in place better and avoids shifting during molding.

2. Improved Accuracy

Since gravity helps with insert placement and plastic flow in vertical machines, the final product has fewer errors. This makes the shapes and sizes of the parts that come out more consistent.

3. Ideal for Small and Intricate Designs

Making small parts or parts with lots of small details is easy with vertical injection molding. Many machines have rotary tables or shuttle systems, which help speed up the production and improve quality without disturbing the insert or mold.

4. Tight Tolerances

There are plastic parts that need to fit together perfectly with other parts. Because molding lets you keep a close eye on things, the parts’ sizes stay within very strict ranges. In this case, the tolerances are very tight.

Benefits for Plastic Manufacturers

Many plastic manufacturers prefer vertical injection molding because it provides several practical benefits for their daily work. Let’s look at some of the main reasons.

1. Space-Saving Design

Vertical molding machines take up less floor space than horizontal ones. This is very helpful for manufacturers who have limited space but want to run multiple machines at once.

2. Faster Production with Rotary Tables

Some molding machines have tables that can turn. This allows the maker to load inserts on one side while the other is molding. This makes things go faster and makes production more efficient.

3. Lower Material Waste

Because the insert stays firmly in place and plastic flows better, there are fewer rejected parts. This helps save plastic and lowers overall costs.

4. Ideal for Small and Medium Batches

While vertical/insert molding can handle large runs, it’s also great for small to medium-sized production batches. This makes it flexible for different project sizes, especially when testing new parts.

5. Safe and Easy to Operate

Many vertical injection molding machines are made with the person who will be using them in mind. It is easier and safer to load them with inserts, and many of them have automatic or semi-automatic features that make it less likely for someone to make a mistake.

Real-Life Uses of Vertical Molding

It is used in many industries, especially when strong, detailed parts are needed. Here are some examples of where this method is commonly used:

1. Medical Devices

A lot of medical tools and gadgets have small plastic parts that are inserted with metal parts. Very careful work needs to go into these parts. A lot of the time, vertical injection molding is used to make parts like medical tool housings, connectors, and sensors.

2. Electronics

Electronic parts like connectors, switches, and plugs often have metal pins that must be molded inside plastic. Vertical molding makes it easier to produce these parts with high accuracy.

3. Automotive Components

Automobiles have lots of plastic parts that hold metal inside, like housings, sensors, and clips. These parts are strong and reliable thanks to the vertical injection molding that goes into them.

4. Consumer Goods

Vertical molding is used in many everyday items like kitchen tools, toys, and gadgets. It helps make small plastic parts that are strong and detailed, which is important for products that need to work well and last longer.

Why Plastic Manufacturers Trust Vertical Molding

Plastic manufacturers are always looking for ways to improve quality and reduce costs. Vertical / insert molding helps them do both. It’s especially helpful for projects that need special attention, like overmolding (molding plastic over a metal or another plastic part) or insert molding.

Vertical machines allow manufacturers to work more efficiently, reduce errors, and produce more complex parts without spending additional time or money. It’s an excellent choice for companies that require flexibility, precision, and strength in their parts.

Conclusion

For making plastic parts with complicated shapes and small details, vertical molding is a powerful method. It saves space, cuts down on waste, and helps plastic manufacturers make accurate products, especially when inserts or tight tolerances are needed.

From electronics to automotive to medical devices, vertical injection molding plays a key role in building the high-quality parts that modern industries rely on.

If you need precise and reliable parts, vertical /insert molding is the way to go, whether you need a few unique pieces or thousands of them.

Need help with complex plastic parts? Contact a trusted plastic manufacturer and ask how vertical molding can help your project today.